Hakurnas factory was founded in 1962 by the fathers of the two current shareholders, Avi Ben-Gal and Miron Bedin; we are the leading lead factory in the Middle East, specializing in responsibly recycling batteries and producing lead and lead alloys. With a commitment to environmental sustainability, we are dedicated to providing top-notch services in the field of battery recycling. In 2012, Hakurnas was registered as a brand in the LME. Join us in shaping a cleaner, greener future by choosing Hakurnas -A Lead Factory for all your lead production and battery recyclers.

We understand the significance of lead as a versatile mineral and chemical element that shares nature's stage with iron, gold, and oil. Surprisingly, nature only accounts for a fraction of the world's lead supply, with an impressive 65% resulting from efficient recycling efforts. We pride ourselves on our commitment to sustainability, as most of our lead comes from the local market, supplemented by carefully sourced imports.

Our global reach is a testament to the quality of our products, with 90% of our production serving international markets and the remaining 10% catering to the military industry and leading battery manufacturers in Israel. With the global demand for lead reaching 13 million tons, its impact on various industries cannot be underrated.

Lead is indispensable in numerous applications, with 75% of its use dedicated to producing car batteries. Moreover, its versatility extends to batteries, metals, protective products against radioactive radiation, energy storage, the printing industry, and beyond. As trailblazers in the lead recycling industry, we take pride in promoting environmentally responsible practices while supplying high-quality lead for the diverse needs of industries worldwide.

we are committed to environmental stewardship, implementing cutting-edge technologies and responsible practices to ensure a cleaner and healthier future

In this crucial step, we prioritize battery circulation, ensuring the responsible collection and initial processing of batteries to kickstart the recycling journey.

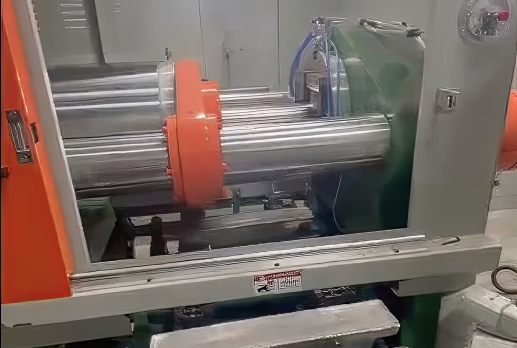

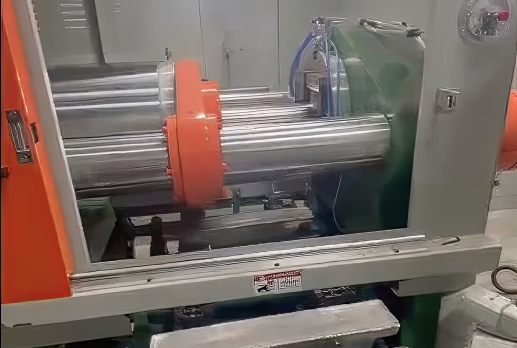

In our advanced Furnace Department, lead components undergo a high-temperature melting process, transforming them into liquid lead through meticulous precision.

The lead undergoes additional and meticulous cleaning processes. The refined liquid lead is then meticulously poured into ingots, ready for use in various applications.

© 2024 Hakurnas Company